The role of a stretch wrapping machine in industrial automation

Wiki Article

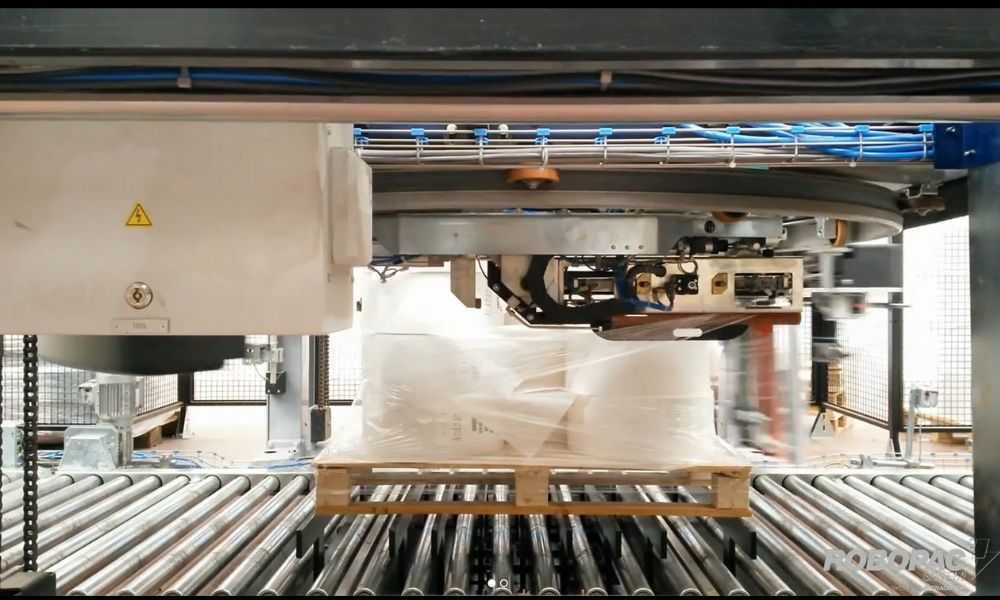

Make The Most Of Lots Stability With an Advanced Stretch Covering Device for Safe Transportation

Advanced stretch wrapping makers provide an ingenious service, covering lots with pinpoint accuracy to prevent moving during transportation. With a collection of features such as adjustable movie tension and automated capability, these machines deliver consistent vertical and straight security while minimizing damages threat. How do these equipments precisely boost load security and efficiency?Recognizing the Role of Stretch Covering in Safe Transport

While several may ignore its importance, stretch wrapping plays an essential role in making sure the secure transport of goods. This procedure includes the use of a very stretchable plastic film that is covered around products, generally on a pallet. The elastic recuperation of the wrap tightly secures the things together, preventing activity throughout transportation.

Secret Attributes of Advanced Stretch Covering Machines

In the realm of logistics and supply chain administration, advanced stretch wrapping machines have actually arised as a game-changer. These equipments are characterized by numerous crucial functions that identify them from their predecessors.Advanced stretch covering machines also include pre-stretch abilities. This attribute enables the movie to be extended before being applied to the tons, making best use of movie use and minimizing expenses. Furthermore, these machines have adjustable controls for movie tension, making it possible for modification based upon load shapes and size.

Ultimately, these equipments are equipped with integrated load cells, which accurately measure the weight of the tons throughout the covering process. This feature ensures the machine changes its procedure based on the weight, consequently avoiding damage and ensuring the lots's risk-free transport. Therefore, advanced stretch wrapping devices provide a mix of automation, performance, security, and cost-effectiveness.

Exactly How Stretch Wrapping Machines Enhance Lots Stability

Making certain that loads continue to be stable during transportation is an essential facet of logistics, and one that advanced stretch wrapping makers master addressing. These makers function by enveloping the load in a safety film that holds all items securely with each other. This reduces the threat of things falling or moving throughout transportation, therefore boosting lots stability.The makers employ a sophisticated covering method that provides not just upright yet additionally straight security. This dual-axis stability further reinforces the lots and lowers the probability of damages or loss. The consistent stress used by the device throughout the wrapping process makes certain that the load is safe and compact.

Possible Price Savings With Reliable Stretch Covering

Beyond enhancing load stability, advanced stretch wrapping devices likewise offer significant potential for price financial savings. These equipments lower the demand for manual work, hence decreasing pay-roll costs. They likewise function quicker and much more successfully than people, resulting in boosted performance.Using innovative devices makes sure ideal usage of stretch movie, which can result in substantial savings in material expenses. Hand-operated wrapping usually results in wastage because of inconsistent use of film. However, a maker uses the correct amount of visit film, eliminating wastefulness.

In addition, the improved lots stability lowers the danger of damages throughout transport. This can possibly conserve businesses from expensive item losses and connected replacement costs.

Last but not least, the machines need minimal upkeep, which converts into reduced fixing and upkeep costs.

Selecting the Right Stretch Covering Equipment for Your Service Needs

While the advantages of sophisticated stretch wrapping makers are apparent, picking the right one for your particular service needs can be a daunting job. Different elements require to be thought about - stretch wrapping machine. Firstly, think about the kind and quantity of products to be covered. Makers vary in capacity and adjustability to cover different shapes and sizes of lots. Second of all, evaluate the rate needs of your procedure. High-volume operations would certainly gain from automatic devices with greater speeds, while semi-automatic equipments may be enough for smaller businesses. Third, think about the maker's sturdiness and upkeep requirements. A robust equipment that calls for very little maintenance might save expenses in the lengthy run. Lastly, take right into account the machine's assimilation with your existing production line. It ought to boost, not interrupt, your workflow. A thorough analysis of these elements can lead services in the direction of the optimum stretch wrapping visit here machine, hence making certain risk-free transport of their items.Verdict

In final thought, advanced stretch wrapping equipments are vital in ensuring tons security throughout transport. Businesses need to internet consider spending in a suitable stretch covering equipment, even more boosting safety and efficiency within their supply chain.Advanced stretch covering makers supply an ingenious service, covering tons with identify precision to protect against moving during transit.Guaranteeing that tons continue to be secure throughout transport is a crucial facet of logistics, and one that advanced stretch covering devices excel in dealing with.Beyond improving load stability, progressed stretch wrapping makers also supply significant possibility for expense savings. High-volume procedures would benefit from automatic devices with greater speeds, while semi-automatic makers might be sufficient for smaller sized companies.In final thought, progressed stretch covering equipments are essential in guaranteeing lots security throughout transportation.

Report this wiki page